ISO 13485

Reach international regulatory compliance for medical devices with this standard.

ISO 13485 – Medical Devices

At each stage of your product’s life, regulatory requirements are scrutinized in the manufacture, delivery, or service stages. Laboratories and other organizations in your industry are expected to exemplify a sound Quality Management System (QMS) to demonstrate best practices.

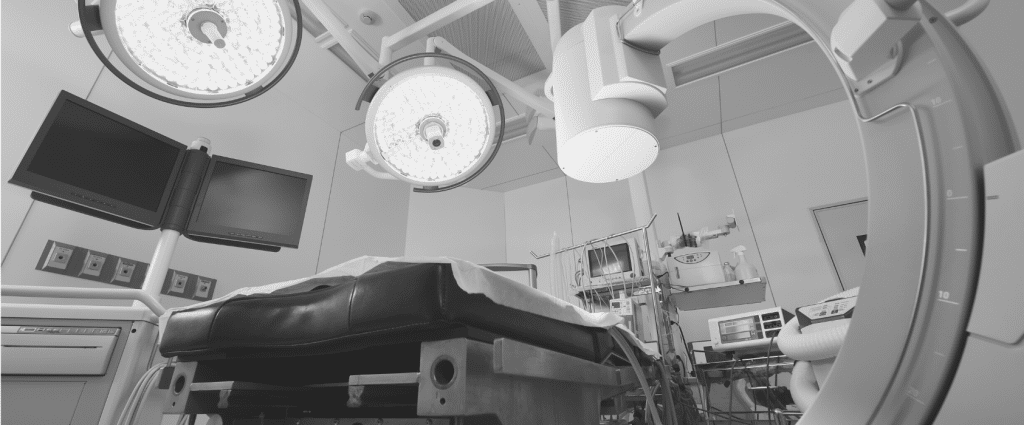

Are you keen to ensure the devices in your medical laboratory are safe, effective, and delivered to a high standard? Do you want to be brought up to speed with national and global requirements for your industry? As a medical device manufacturer, the ISO 13485 standard is the most accepted global standard of its kind. If your business wants to put competency at the forefront of your operations, IMSM can talk you through how this certification will improve and validate how you work.

Downloads

What is ISO 13485?

Certification ensures that medical devices in healthcare settings are designed, produced, installed, and serviced to the highest standards. ISO 13485 originates from the need to meet client obligations and the regulatory and legal specifications for business owners involved in the manufacture of medical devices manufacturers.

Adopting the ISO 13485 standard into the heart of your practices means you will build a clear, practical foundation to address these specifications by taking control of your supply chain with a robust framework that will reduce costs. Your business will also demonstrate a commitment to safety, quality, and competence for medical device manufacturing, recognized worldwide.

Throughout the ISO 13485 certification process, you will be guided by a dedicated ISO consultant. They will start by assessing your business and then help you to use the results to improve your medical device manufacturing quality management system. We work with the senior management team to ensure the ISO 13485 standard framework is embedded throughout your organization before you are assessed by a third-party auditor who awards the certification.

Read how to get ISO 13485 certification.

What are the benefits of ISO 13485?

- Taking control of your supply chain

Why get ISO 13485 certification? A good tell of whether the organizations in your supply chain are quality-focused is to see if they are ISO 13485 certified. You are an original equipment manufacturer (OEM) of medical devices, so you are responsible for ensuring that every producer within your supply chain complies with regulations. Are they all working to identify risks and prevent defects in their own processes? Verification can be tedious and unrewarding, so you should get ISO 13485 certification as a mark of quality and competence. - Ensuring control processes are robust in every step of your medical product’s life

From development to manufacturing to distribution, every stage of your product’s journey must be carefully controlled to meet regulations and avoid inadequacy. ISO 13485 certification makes the process less overwhelming by providing you with a solid, easy-to-manage framework to help you manage your control processes. - Reducing costs through a more efficient QMS

The ISO 13485 standard enforces best practices in a medical product’s lifecycle. It also addresses the efficiency of these practices. With a methodical approach to medical device manufacturing, you will have a logical plan for your workforce, saving time and reducing waste. - Becoming up-to-speed with the needs of regulatory authorities in your area

Who needs ISO 13485 certification? In a time when public health is at the forefront of everyone’s mind, authorities are more stringent than ever when it comes to regulating the medical device manufacturing industry. The ISO 13485 standard provides medical device manufacturers with a useful framework that has already considered that there will be legal requirements associated with the medical device, making these easy to control and manage. - Qualified with an internationally-recognized certification

What does it mean to be ISO 13485 certified? It’s the leading qualification of its kind, meaning it is recognized across the world as a mark of quality and competence. Certification gives you the confidence to emerge onto the global market and open yourself to new business opportunities.

Steps to getting ISO 13485 certified

Working towards ISO 13485 certification with IMSM is a trouble-free, step-by-step approach.

- Initial consultation

We help you outline your goals, focusing on what your business wants to achieve and how it defines success, particularly in relation to your client’s requirements. You and your ISO consultants will agree on reasonable outcomes and delivery dates. - Producing your organization’s ISO 13485 manual system documentation

Next, the IMSM consultant will audit your existing procedures and help you document the new systems that will help deliver success – both existing and how you will improve these. The manual system documentation sets out how your business should operate going forward so that it can deliver ISO 13485.

You will be able to view the manual system documentation, along with most other relevant documentation, on our client portal IMSMLoop. It offers a comprehensive insight into the progress of your ISO implementation, along with copies of the relevant audit reports, certifications, and any necessary corrective actions. The portal serves as a central hub for tracking your ISO journey. - Training you to adopt the ISO 13485 framework

While the manual system documentation is a vital document moving forward, it is even more important that it gets put to practical use. We work with the senior management team to ensure the framework is embedded throughout your organization. We can also develop and deliver tailored training for staff to ensure that the understanding and implementation of ISO 13485 is watertight. This will create consistency across your organization, transforming your business from day one so it is optimized for efficiency, continual improvement, and greater profitability. - Submission to a third-party external auditor

Before you can be awarded the ISO 13485 certification, your organization applies to the third-party certifying body that you have selected to conduct your audit. This audit objectively determines whether your business conforms to ISO 13485, and the relevant accompanying documentation is accessible through our client portal, IMSMLoop.

As we have provided excellent support and guidance to your business every step of the way, you can rest assured that your ISO 13485 certification will be successful.

Why IMSM?

Simple: We make it simple. Since 1994, we’ve been helping businesses achieve ISO certification and have over 150 experts worldwide. With 15,000+ clients trusting us to implement their ISOs, we have proven to be experts capable of handling the logistical heavy lifting, saving your company precious time. With a transparent fixed fee, flexible approach, and real-time access to updates, documentation, and an array of other features through IMSMLoop, we work with your organization to make ISO 13485 implementation as straightforward and beneficial as possible.

We strive to do this with our:

– World-class gap analysis

– Experienced and diverse ISO consultants

– Regular updates, provided through IMSMLoop

– Flexible terms and contract

– Fixed fee

– Full implementation

How can ISO specialists help your business?

Getting started with ISO 13485 certification might seem daunting; this is often the reason why businesses enlist the help of an ISO consultant. For thirty years, we’ve supported and guided organizations like yours through certification. Our experienced consultants take the lead on auditing your business, helping you use the results to enhance your quality management system. If necessary, there is also plenty of room for training.

FAQs

- Is ISO 13485 certification mandatory?

ISO 13485 certification is not itself mandatory; however, by achieving ISO 13485 certification, your practices will be brought up to date with international standards and, therefore, compliant with local regulations.

Read about medical devices compliance for South Africa. - Who needs ISO 13485 certification?

Medical device manufacturers will benefit from ISO 13485 certification. The ISO 13485 standard is internationally recognized, evidencing your compliance with regulatory and legal requirements to meet your client’s needs. In addition, ISO 13485 certification showcases your commitment to quality and efficiency. - How to get ISO 13485 certification?

Medical device manufacturers often find that the assistance of expert consultants helps them to easily implement ISO 13485 into their core processes. With IMSM, our consultants work directly with you to ensure your QMS works for your organization. We help you design your control requirements in line with the standard, then submit you to a recognized, third-party certification body who will audit your business and get you ISO 13485 certified.

Find out more about getting certified here. - How long does it take to get ISO 13485 certification?

The length of time taken to get ISO 13485 certified depends on the size and complexity of your company. It is estimated that it can take 4-6 months for companies with less than 50 employees. For larger companies, it can take 6-12 months as complex manufacturing processes like sterilization can prolong the process. - Is ISO 13485 required for CE mark?

It is not mandatory to be ISO 13485 certified, but to be awarded the CE marking, you will need to provide evidence through QMS as required by the MDR. If you’re not ISO 13485 certified, you will need to convince the governing body that your QMS is equally as good or better than one that has been built using the ISO 13485 framework.

ISO 13485 Blogs

Take a look at our most recent blogs relating to ISO 13485

What is ISO 13485?

Medical devices are considered a fundamental and essential component in diagnosing and treating medical conditions within health systems.

How to get ISO 13485 certification

If you’re a medical device manufacturer, it’s likely that ISO 13485 will be on your radar. This internationally-recognized standard ensures such vital technology as yours is safe, effective and delivered to a high quality.

Contact Us

For a free Quotation or On-Site presentation by an ISO Specialist, contact us today!

IMSM Inc

1500 District Avenue

Burlington

Massachusetts

MA 01803

USA